autoclave chamber leak test|autoclave leak test failure : member club An air leak in a sterilizer's plumbing or chamber and any air trapped in the autoclave can play a . With a sophisticated design and excellent visibility, the panel is easy to operate and maintain, .Find out all of the information about the Nüve product: laboratory autoclave NC series. Contact .

{plog:ftitle_list}

In order to comply with currently acceptable and achievable limits in sterilization parameters, it is necessary to employ appropriate instrumentation and equipment to control the critical .

While it’s not a substitute for sterility assurance testing, the Bowie-Dick test cycle demonstrates proper air removal from the chamber of a pre-vacuum autoclave. Pockets of cool air can form inside the chamber of a pre-vacuum autoclave, acting as . See moreWhat is a Bowie-Dick test? A Bowie-Dick test is a standard operational test that laboratories can use to determine proper air removal from their . See more

A vacuum leak test is used to determine the air-tight integrity of a pre-vacuum autoclave’s chamber and plumbing system. This test . See moreAn air leak in a sterilizer's plumbing or chamber and any air trapped in the autoclave can play a . The Vacuum Leak Test programmed on your autoclave only measures the .

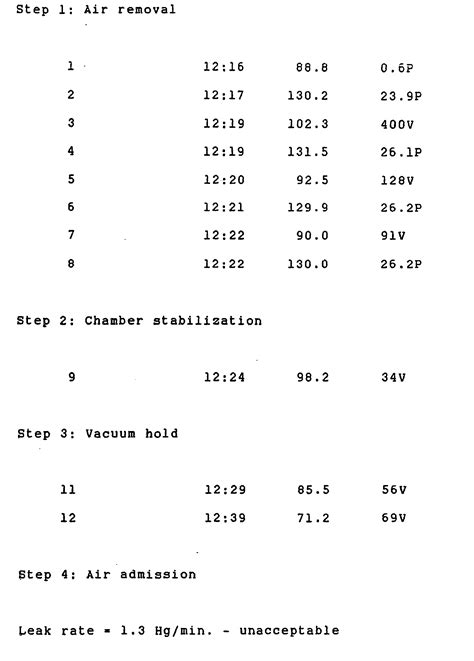

Chamber pressure leak test It’s used for autoclaves that are not equipped with a vacuum pump (counterpressure autoclaves) It is not standardized and the definition of rational limits are the responsibility of the autoclave user For tightness testing purposes, the chamber is pressurized by compressed air up to 2 to 3 bar abs BOWIE-DICK TEST: Check our full article on the Bowie dick test. 2. LEAKAGE TEST: An air leakage test for autoclave chambers is done to find out any leakage from the chamber. Air leakage test is used to establish that the quantity of air leakage into the sterilizer chamber during the period of vacuum does not exceed the level. air leakages will .The vacuum test comprises several phases which are defined in the program sequence of the autoclave:. Evacuation phase: the sterilization chamber is evacuated until the required vacuum pressure is reached. Equalization time: This is followed by an equalization time of 5 minutes to ensure that the pressure in the chamber is stable.. Measuring time: The measuring time is 10 . Vacuum leak testing is a simple operational inspection that should be incorporated into standard operating procedures wherever a pre-vacuum autoclave is used. Vacuum leak testing is also known as chamber integrity testing. The vacuum leak test verifies any leaks in the Steam Steriliser Autoclave.

The Vacuum Leak Test is used to evaluate the air-tightness of the chamber and pipework of a pre-vacuum autoclave. In this test, the piping and parts of the autoclave are subjected to vacuum conditions, and the amount of vacuum depth lost over a predetermined time is recorded.To perform autoclave testing, autoclaves include a fully automated vacuum Leak test cycle program. This program evacuates the chamber to a set vacuum level, holds it for a specific time, and then checks the pressure again. Any increase in pressure indicates air leaking into the chamber, resulting in a failed leak test. Both the Bowie Dick Test .

leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH. 2 Overview • Fundamentals of DP method –LFC, P, V (different types) –pressure curve / course . Test chamber is evacuated below the. water vapor pressure (e.g. 23.4 mbar absolute @ 20 °C)A vacuum leak test is used to determine the air-tight integrity of a pre-vacuum autoclave’s chamber and plumbing system. A vacuum leak test is performed on an autoclave to check for any leakage. This test is also called a chamber integrity test. The test exposes the autoclave’s plumbing and components to vacuum conditions and measures how . Make sure that the disposable test-pack is the only item in the chamber during the diagnostics test. If you have questions about Bowie-Dick test troubleshooting, contact our team. . The vacuum leak rate test is just one of the leak testing methods we use to ensure proper operation of highly specialized equipment. If you have questions .

Vacuum leak test: Objective: To verify the leakage in sterilization chamber during vacuum hold time when the sterilizing chamber is empty. Principle: These tests are designed to show that the sterilizer chamber does not leak in empty chamber. Leakage of air into the chamber is not acceptable for two reasons: 1.The different tests are follows for qualification of autoclave are: – Vacuum leak test Bowie-dick test Heat distribution study. Empty chamber; Loaded chamber; Heat penetration study VACCUM LEAK TEST: – This test is used to verify the leakage in sterilization chamber during vacuum hold time when the sterilizing chamber is empty.

Priorclave autoclaves include a fully automated vacuum Leak Test Cycle program. Running this program automatically checks the integrity of the chamber and interconnecting pipe-work. During a Leak Test Cycle, the autoclave evacuates the chamber to your established vacuum set-point, then holds for five minutes before checking the pressure again. The Vacuum Leak Test programmed on your autoclave only measures the integrity of the sealed pressure vessel and associated piping to ensure air is not admitted to the sterilizer during the vacuum drawdowns. . and any residual air in the chamber will naturally migrate to the test pack. Step 3: Ensure the chamber is empty. Only the sterilizer .They should be labeled and placed at the front, middle and back of the autoclave chamber. Study Procedure: Chamber Leak (CL) Test: [][]Thermocouples and reference pressure transducer are introduced into the chamber via the validation port. Then, the port and doors are sealed properly. There is a cycle, named as “Vacuum air test” cycle for .

vacuum leak test acceptance criteria

If the chamber of autoclave fails in vacuum leak test, the autoclave shall be given for maintenance .The sterilization load shall be taken only after the chamber passes in vacuum leak test. Vacuum leak test of chamber is to be done once every day before start of any operation. Vacuum leak test verify the any leakage in autoclave. Performed in daily once (first cycle). As per guideline HTM -2010 Vacuum leak test should be performed on weekly once. Vacuum leak test is a critical test because verify the chamber leakage. Vacuum leak test applied the vacuum inside the chamber and wait for reach the vacuum as per set point .

describe autoclaving process

1.3 mbar/min or less during the 10 minutes that the test lasts for; if the leak rate is higher, the test is a failure and you will have to check the airtightness of the device’s hydraulic circuit. How it works and when. This test—for class-B autoclaves—is available with all autoclaves that offer a specific cycle. It takes around 20-30 .Today, most autoclaves have an automatic program for a routine tightness test , which is "analyzed" by the pressure measurement systems of the autoclave itself. Discrimination capacity not better than 10 mbar → test time is generally increased to 16 minutes and the acceptable tightness loss becomes 20 mbar Air leakage test: Chamber vacuum .

Repeat the test 3 times. 21.2 Dryness: the saturated steam witht the dryness value not less than 0.95 where the dryness value deotes the mass of gas fraction in the mass of saturated steam. Basically, excessive moisture cause damp loads and too little moisture makes ultra superheat. Repeat the test 3 times. 21.3 Air Leak: If air is able to leak into the autoclave chamber, the steam will be unable to penetrate the load to the point of total sterilization. Unwanted Condensation: Occasionally, condensation gets trapped in the jacket of the autoclave, .The Leak test or Vacuum test is designed to examine air-tight integrity and the presence of leaks in an autoclave chamber and pipes. The chamber is brought to vacuum conditions of 7 kPa (after approximately 200 seconds in the above graph), and all valves and motors are closed for 5 minutes, enabling pressure stabilization.Benefits of a Vacuum Leak Test. Determine the air-tight integrity of an autoclave's chamber and plumbing system; Measure how much vacuum depth was lost over a given period of time; Regular testing allows greater confidence in the integrity of the chamber and the plumbing;

of a chamber and displacing the air, which is heavier than steam, by removing the air from the bottom of the chamber). A typical pressure vs. time graph for a liquids cycle is shown in Figure 6. Basic Validation Approach Installation Qualification (IQ) The IQ process is intended to demonstrate that the autoclaveThe chamber must be cleared of all air to ensure that the steam contacts all of the device surfaces to be sterilized. The process for conditioning depends on the type of steam sterilizer being used. . Many dynamic air removal steam sterilizers have a leak test built into the machine. This test measures the leakage of air into the chamber .A successful Bowie and Dick test indicates rapid and even . penetration of steam into the standard test pack or reduced test pack.” ISO 17665-1, Section 12.1.6 “If the sterilization process relies on the removal of air from the . sterilizer chamber in order to achieve rapid and even amounts of steam into Vacuum Leak Test: Essential for pre-vacuum autoclaves, this test ascertains the chamber’s integrity, ensuring there are no leaks that could compromise the sterilisation process. Biological Indicators: These are microorganism-based tests which are introduced and then retrieved from the autoclave to confirm the complete eradication of bacterial .

Autoclave is used for sterilization of various articles in microbiology laboratory as well in sterile manufacturing. This article has procedure for autoclave validation including steam penetration, heat distribution and penetration, bio-challenge study, estimation of F0 value and acceptance criteria of steam sterilizer validation in pharmaceutical industry.

sterilizer leak test parameters

steam penetration test autoclave

Buy or sell your Autoclaves and sterilization equipment through Integris Equipment. (888) 228-7564 We keep many popular models in stock. We deal with new, used and refurbished equipment. Click the link to browse our .

autoclave chamber leak test|autoclave leak test failure